Flawed From The Factory: Taking A Hard Look At The Many Failure Points Of The 68RFE

The 68RFE has arguably more demons than any other automatic transmission developed for use behind a diesel.

For more than 15 years now, the 68RFE six-speed automatic behind the 6.7L Cummins has been notorious for premature failure.

Since midway through the 2007 model year, the 68RFE has been available in Ram trucks. And for more than 15 years now, the six-speed automatic behind the 6.7L Cummins has been plagued with failures. Even at the stock power level it’s relatively easy to find some of the 68RFE’s weak links. On the performance side, enthusiasts have long-known about the Low/Reverse sprag’s propensity to fail when boosted, four-wheel drive launches are performed in first gear. And many more have come to experience the highly-common Overdrive clutch failure that occurs when the 6.7L Cummins is placed under load. But the 68RFE’s problems run much deeper than that. In fact, this transmission arguably has more demons than any other automatic ever developed for use behind a diesel engine.

Teaming up with WP Developments, a group of 68RFE die-hards from Otterbein, Indiana who are determined to make this transmission live in high-horsepower applications, we’re pinpointing all of the infamous six-speed’s shortcomings this time. From the familiar 4C clutch and Overdrive clutch failures, to broken hard parts, and all of the flaws within the valve body, never before has a more thorough failure analysis been performed on this transmission—so make sure you hold onto this link forever. And rest assured, with all the bad comes plenty of good. In closing, we’ll spotlight a host of aftermarket solutions to the 68RFE’s many problems—including the first-ever full manual valve body for the Chrysler six-speed.

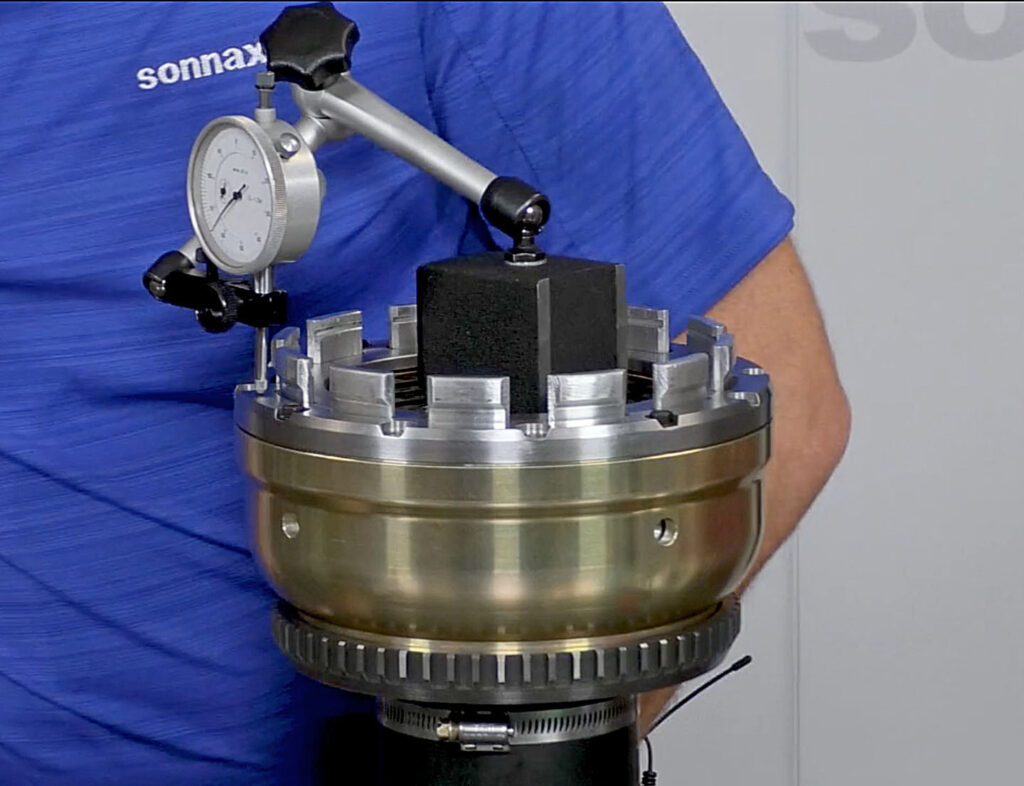

According to Sonnax, a company that arguably has more R&D time invested in the 68RFE than any other transmission parts manufacturer, the Overdrive clutches are the most common failure point. Aside from the added power and larger tires many truck owners force their 68RFE to contend with, the Overdrive clutches are some of the thinnest units to be installed in any transmission. The OEM clutches (right) are single-sided with each steel core measuring just 0.034-inches thick.

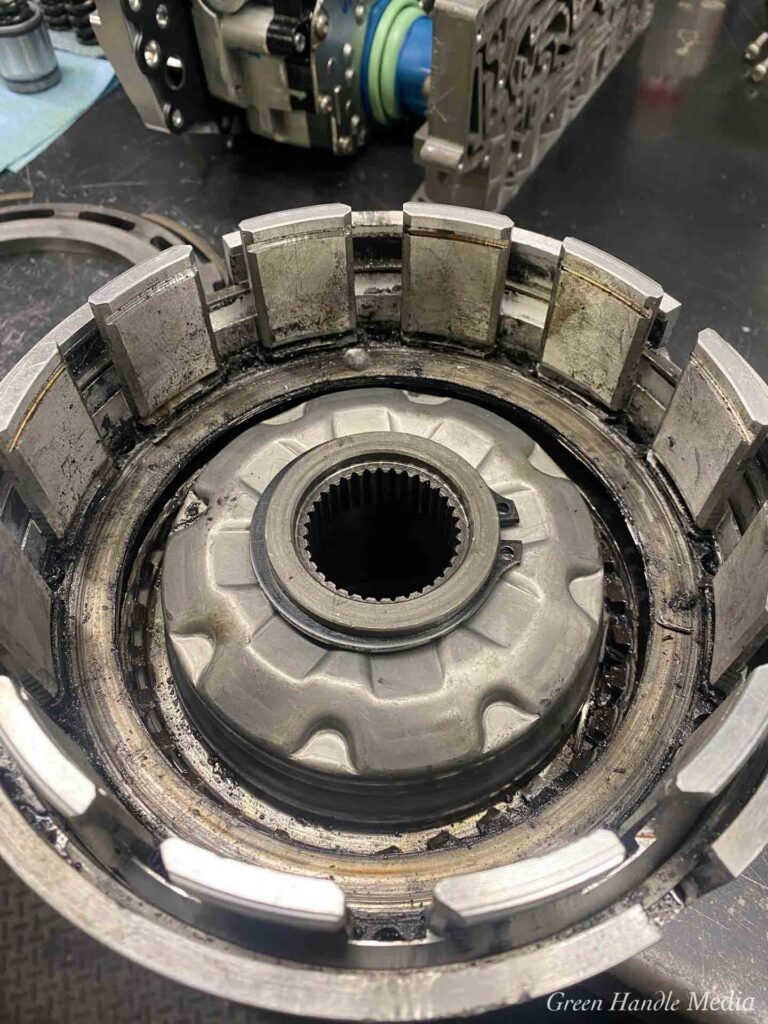

The Overdrive clutches’ lack of size means they don’t dissipate heat very effectively, which means they can easily become warped, pushing clearances out of spec—not to mention that the overdrive housing itself is prone to flexing… The Overdrive clutch problem becomes amplified with extra torque (tuner) and rolling mass (big wheels and tires) in the mix. These burnt up Overdrive clutches were pulled out of a stock 68RFE that was torn down at WP Developments.

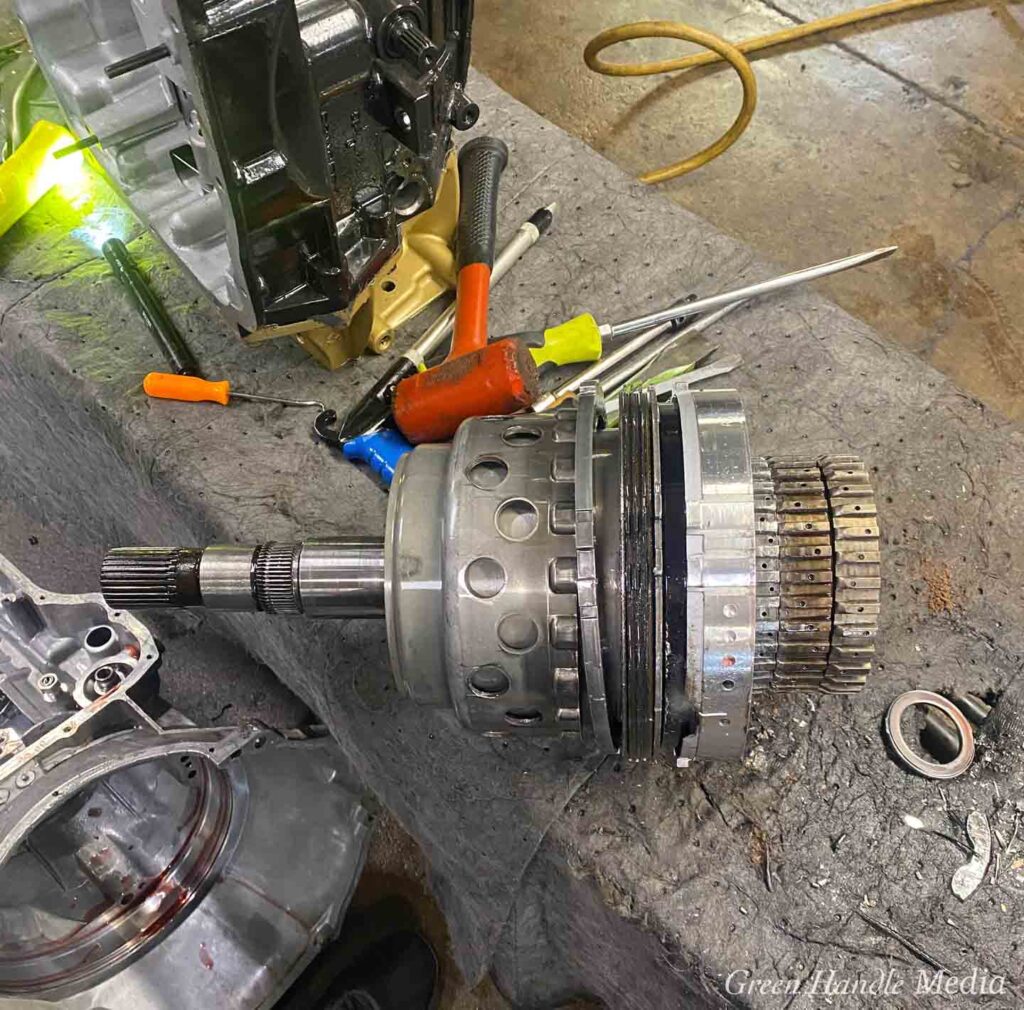

This is a familiar sight when you peer into the Overdrive drum following a clutch failure. According to Ethan Patterson, owner of WP Developments, there is simply nothing in place to keep the factory Overdrive clutches from flexing, distorting, and creating heat. He also offered that, in addition to the inherent flaws of the factory clutches, the Solenoid Switch Valve (SSV) can also contribute to Overdrive clutch failure, as well as the valve body not sealing. Patterson and his team have seen the frictions eat into the inner drum in the past, and even destroy the entire input assembly in some cases.

One of the best solutions for Overdrive clutch issues is the Smart-Tech Overdrive clutch housing kit from Sonnax. Its comprehensive kit includes an Overdrive/Reverse housing that’s modified to hold a physically taller clutch pack, which is made up of custom BorgWarner frictions. The clutch pack boasts 20-percent more clutch capacity and 16-percent more Overdrive apply area, which results in firmer, better controlled shifts. The Sonnax kit also comes with a bolt-on anchor plate designed to keep the clutch pack from flexing, thereby eliminating the distortion that contributes to excessive heat build-up.

Another issue the Sonnax Smart-Tech Overdrive clutch housing kit solves is this common occurrence, in which the housing breaks where the snap-ring for the Overdrive clutch is retained. The guys at WP Developments believe this failure is usually the result of high line pressure. They liken it to bending a piece of metal back and forth until it eventually snaps into two pieces. Higher line pressure isn’t a good thing when the internals aren’t designed to handle it.

While the Overdrive clutches are considered the weakest link in the 68RFE, 4C clutch failure is highly frequent, too. Most 4C problems show up with the transmission in fifth gear, even though the 4C is applied in second and third gear as well. In particular, the 4C snap ring is notorious for working its way out of its groove during pressure spikes.

WP Development’s go-to solution for the 4C snap-ring dilemma is to install one of these in its 68RFE builds. It’s a billet snap-ring retainer that encloses the snap-ring in order to keep it locked in place in high pressure applications.

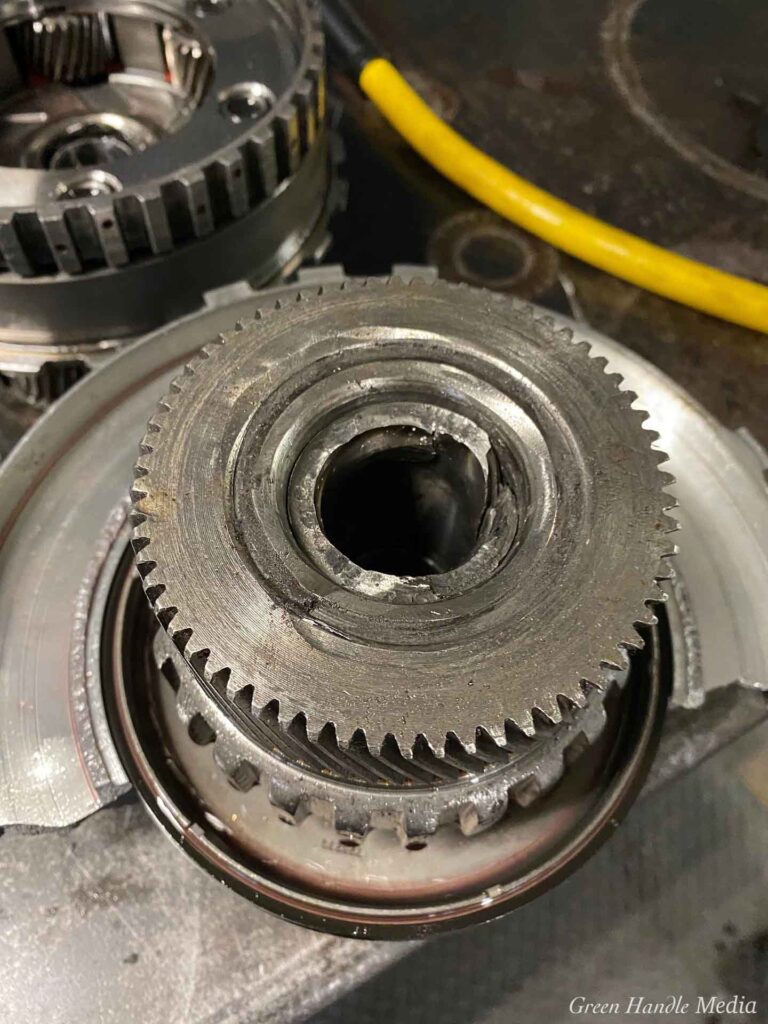

This carnage is the result of a TCM bind-up when two clutches were fighting each other. It’s the 4C clutch hub with a broken Overdrive hub in it. According to the folks at WP Developments, who took delivery of the Ram that suffered this failure, the truck was merely serving as a tow-rig—with little, if any, power adders.

Low/Reverse sprag failure is well-documented in high stress situations such as boosted four-wheel drive launches, truck pulling, or being stuck in a mud hole, but the real reason it fails may surprise you. The L/R element is held in first gear and reverse only (in second through sixth gear it is in free-spin), but roughly midway through first gear the L/R clutch turns off, regardless of what TCM calibration is in your truck. It is this shock load—which you can do nothing about—that takes out the sprag. Now you know why everyone says to launch a 68RFE in second gear rather than first…

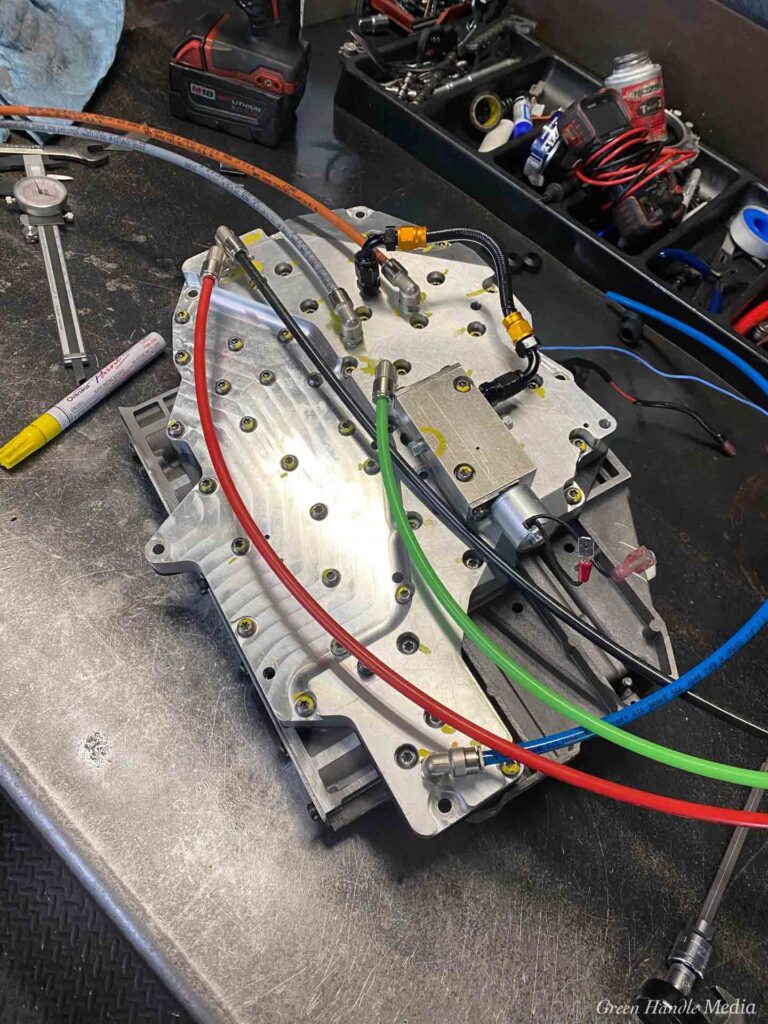

Valve body issues are rampant in the 68RFE and the biggest problem is cross-leakage (i.e. bleed-over). You’re looking at WP Development’s primary means of learning about the valve body’s cross-leakage and actual vs. desired psi in each clutch circuit. In their own words: “This is how we made the 68RFE clutches last and hold under excessive power, as well as what allowed us to watch the on-coming and off-going clutch pressure.” According to them, this is vital in both shift timing and shift quality. “Being able to see exactly how much bleed-over we have in each clutch is key in making the changes needed to cure it.”

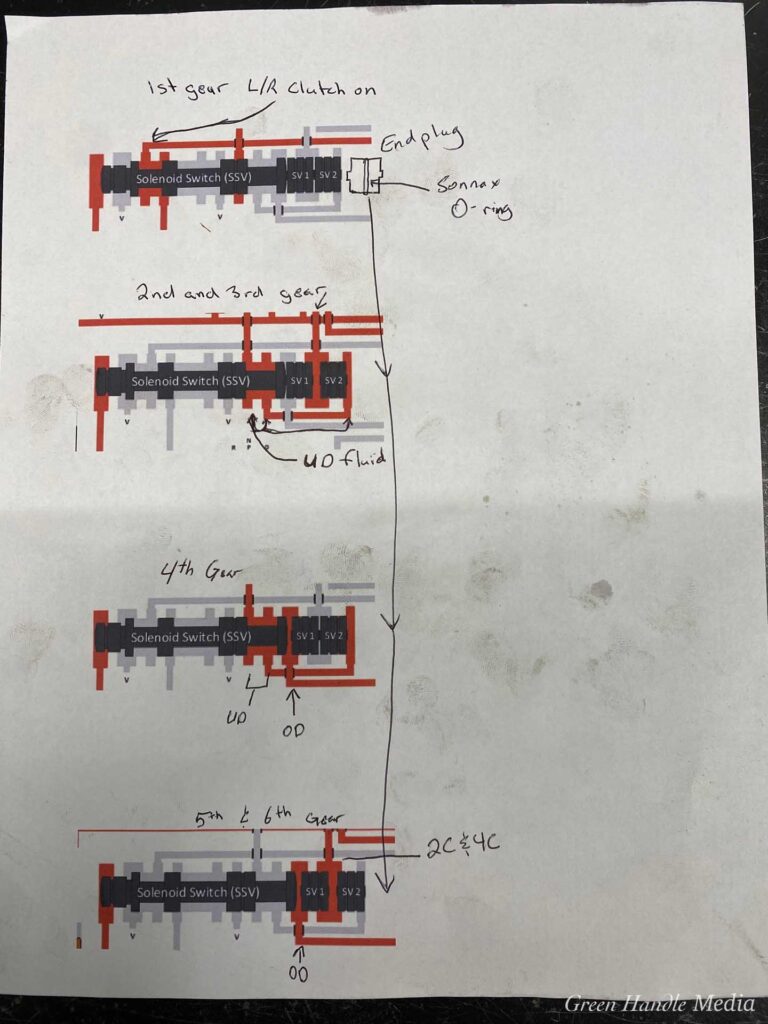

In these diagrams you get an idea as to what channels feed into the SSV (Solenoid Switch Valve) bore and what the SSV’s function is. In pre 2019 versions of the 68RFE there was no torque converter clutch (TCC) lockup solenoid, so the SSV was tasked with performing two jobs. In these earlier 68RFE’s, the SSV feeds the Low/Reverse clutch in first gear, but when the transmission shifts into second gear it effectively becomes the TCC lockup solenoid.

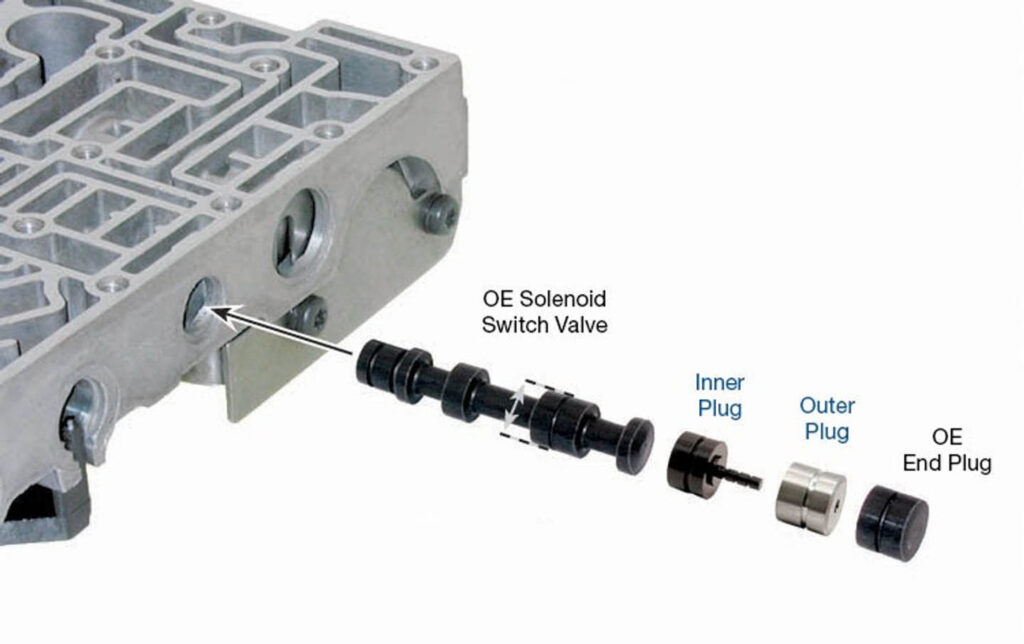

Unfortunately the SSV is prone to bore wear (often from excessive debris in the pan) and plug hang-up. This wear leads to cross leakage and pressure loss, with fluid escaping into the pan rather than being applied to the clutch. The end result can be burnt 4C and/or Overdrive clutches, bind-ups, and an engine that stalls due to improper lockup—not to mention various codes being thrown. According to WP Developments, every single 68RFE benefits from boring the valve body out and putting an aftermarket SSV in place. Sonnax’s SSV plug kit is shown here.

This Sonnax vacuum test station is a vital part of WP Developments’ 68RFE program. It reveals the condition of the valve bore and is employed both before and after machining the valve body to accept oversized valves. The lower the number, the more it bypasses fluid, which leads to eventual failure of the clutch or torque converter.

As we alluded to earlier, beginning in 2019 the 68RFE received a dedicated TCC solenoid block (shown), but the change wasn’t without its own unique set of issues. First, if you find yourself swapping transmissions or valve bodies an OEM software called wiTECH must be used to program the correct PI curve. The process calls for taking a QR code scanner and entering a 46-digit sequence of numbers to essentially convey to the computer how quickly (or slowly) it reacts to voltage. Additionally, WP Developments tells us that an important TSB was issued for ’19 model year trucks that calls for an update on the TCC solenoid block. Failure to perform it will likely ensure premature converter failure.

Meet WP Developments’ ’19-newer upgraded valve body. It has a solution for every 68RFE valve body problem. The upgraded unit boasts a RevMax billet channel plate, a bonded separator plate (to ensure there are no cross leaks), Sonnax accumulators that not only move the sealing surface but that also keep the accumulator off the bore by way of guide rings, and a fresh OEM solenoid pack. Further enhancements include a TransGo SSV, HD accumulator plate (with Loc-Tite on the bolts to keep them from backing out), and L/R switch valve. Over-pressure relief is also built into its valve body for instances where voltage surges and pressure spikes.

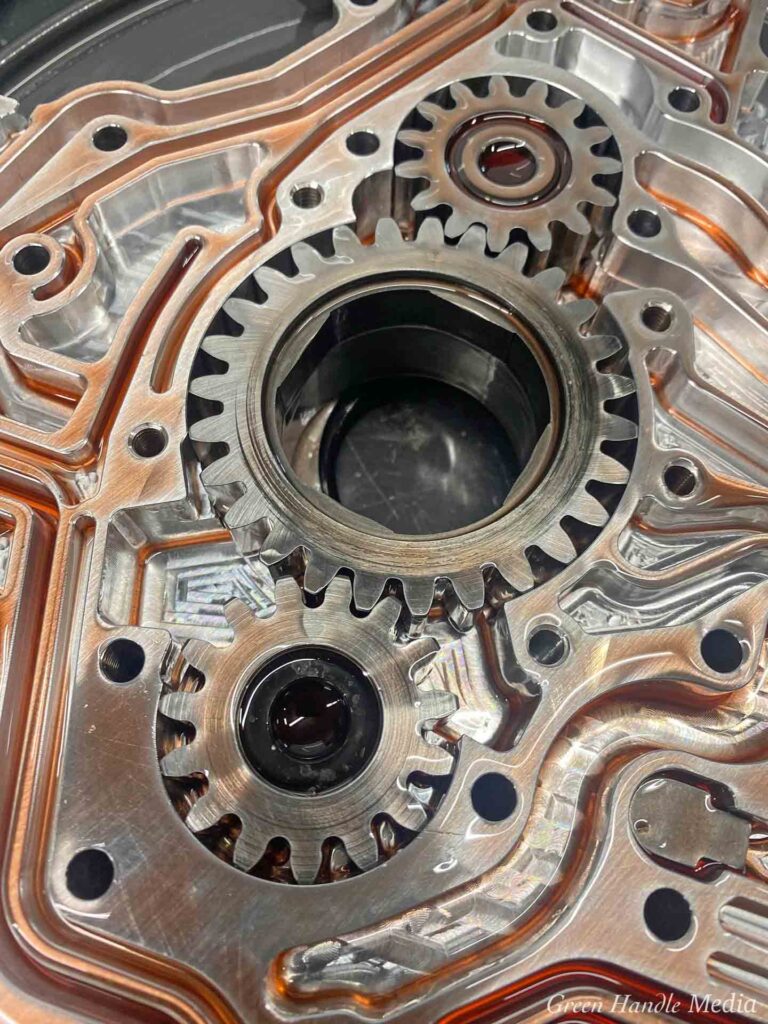

Oil pump failure is a common occurrence in the 68RFE, and the pump usually incurs damage after the torque converter fails. These scored front pump gears are indicative of the converter building excessive heat, expanding (i.e. ballooning), removing clearance, and effectively pushing the pump gears into the housing. Factory flex plate failure can also cause this, which is why WP Developments recommends an upgraded flex plate be included in any 68RFE rebuild.

Just when you hoped the damage from a broken input shaft might be minimal… If you look closely, you can see a hairline crack that spread across the transmission pump body. While this type of catastrophic failure isn’t common, it can happen when the aforementioned input shaft breaks or when excessive thrust pressure forces the pump toward the engine.

This particular 68RFE failure was extremely devastating. Upon tearing the transmission down, the folks at WP Developments discovered a cracked pump, burnt clutches, and a center support that had snapped completely in half.

Taking a closer look at the previously shown 68RFE carnage, we can see that the shaft is seized within the reaction carrier. Also notice all of the metal debris. It was present throughout the transmission, which all but made the unit a total loss for the truck’s owner.

As a result of Overdrive hub failure, the back half of this 68RFE has essentially been welded together. The shaft has also been sheered and is stuck in place. It’s a devastating chain of events, and one that got started in this case with a TCM bind-up where one clutch was fighting another.

One of the first inspection points for transmission failure exists in pulling and inspecting the pan. For the guys at WP Developments, finding this much material in the pan and magnetized to the drain plug means it’s 100-percent time for a rebuild. In this specific 68RFE (and because of the kind of debris on the bottom of the pan), it was apparent that the torque converter had let go.

Other than throwing huge torque at the 68RFE, one of the quickest ways to kill it is through maintenance neglect. And though the Torrington bearing shown can fail in multiple ways, WP Developments determined that this particular unit died from a lack of lubricity due to a plugged filter. Changing the pan fluid and filter at the proper intervals is key to keeping a 68RFE alive. For DIY builders, WP Developments’ Ethan Patterson stresses the importance of making sure these bearings face the right direction when installed, and to always check your shaft end-play.

These burnt reverse clutches have been exposed to prolonged instances of high heat. There are only two reverse clutches in the 68RFE, one being the Low/Reverse clutch located at the rear of the transmission. The other clutch, which is pictured here, is located at the back of the Overdrive drum. Reverse clutch failure is common when truck owners back up heavy trailers in rear-wheel drive, and where immense strain is placed on them. WP Developments’ best advice here is to back a heavy trailer with the transfer case locked in 4-Low.

Another reverse-related problem surfaces after the 68RFE sees so many cycles from forward to reverse, and entails the planetary pins walking out of place. From the factory they’re pressed in, and when they back out they can essentially wreck the entire back half of the transmission. Here you can see WP Developments’ permanent fix for the problem: rear planet pins welded into place. According to Patterson, “every 68RFE build should have this fix, or you could see your transmission in two separate pieces.”

Within the 68RFE there are bleed orifices that vent air out of the clutches at all times. The guys at WP Developments stress that you have to be careful when replacing these with aftermarket versions, as the bigger orifice shown will allow too much bleed-off and in turn lower the transmission’s internal fluid pressure when the clutch is applied. When this happens you get slippage and ultimately premature clutch failure.

You may have heard about Ram’s massive recall regarding the fire risk associated with the 68RFE’s sub-par venting. You might also remember reading that the truck maker had no immediate solution for the recall… According to WP Developments, the factory transmission breather (which is too short to begin with) collects dust, plugs up, and causes excessive internal pressure to build up and blow the dipstick out. The company’s breather kit includes an aluminum catch can, breather filter, 3/8-inch hose, and everything required to mount it to the driver side of the transmission case. If excess pressure does build up, the catch can collects it rather than allowing hot fluid to spray all over the engine and/or the street or track.

WP Developments addresses the 68RFE’s factory shortcomings in every transmission it builds, but for higher horsepower trucks and those looking for added insurance, most customers opt for the company’s 650 or 800 series units (the numbers denoting the horsepower level they’re rated for). The 68RFE-650 comes with a Sonnax billet input shaft, one of WP’s billet triple disc converters, a high-psi pump and valve body, a billet 2C piston, a Sonnax Overdrive drum, a billet 4C retainer, and a heavy-duty low roller sprag.

Full Manual Valve Body 68RFE

It’s no secret that the diesel industry is hungry for a way to make the 68RFE live at high horsepower—and the folks at WP Developments may have found it. The company’s full manual shift valve body is the first of its kind for the 68RFE platform. By taking first gear and fifth gear out of the equation, it effectively transforms the transmission into a four-speed automatic. The direct result of killing off first and fifth gears is that the L/R sprag and 4c clutch failures are eliminated. Additionally, WP Developments deletes the problem child SSV. Finally, its full manual valve body places converter lockup and the overdrive shift on demand for the driver, available via the touch of a button.

WP Developments’ Ethan Patterson On The Progression Of 68RFE Technology

“As an industry, I believe the 68RFE is 1,000 times better than what we had even just five years ago. New developments have improved its holding capabilities as well as its longevity. We released our manual valve body to help bring these newfound reliability improvements into the high-horsepower street and ‘strip segment. Our manual valve body allows us to use the four strongest gears in the 68RFE. We eliminate the failure rate of the Low/Reverse sprag by using second gear as our first gear and we also remove fifth gear, which is arguably the weakest gear the 68RFE has being that the 4C clutch is so small. I think you’ll see 48RE swaps slow down as more people realize you can have the same dependability in a ‘68 and the same—if not better—shift feel with the manual valve body setup.”

Written by Mike McGlothlin