The Duramax: 25 Years Later

A quarter of a century ago, GM announced plans to introduce the 6.6L Duramax we’ve all come to know and love.

It was 25 years ago this week that a press release from General Motors told of a brand-new, “Duramax 6600” on the horizon. In its announcement, the automaker promised a new V-8 diesel platform that would deliver “best-in-class horsepower and torque, operating quietness and smoothness, and durability and reliability.” Unknown to the public, development on the new cast-iron block, cast-aluminum head, 90-degree V-8 had already commenced in 1998. A joint venture between GM and Isuzu (DMAX Ltd.), it was a project that received ‘round the clock attention thanks to the 14-hour time difference between Detroit (GM) and Japan (Isuzu).

Segment Firsts

The initial 6.6L Duramax, RPO code “LB7,” would bring a host of firsts to the heavy-duty pickup truck segment. Among its exclusive features were: aluminum cylinder heads, an induction hardened block, and a cutting-edge fuel delivery system known as high pressure common-rail injection. GM’s game-changing V-8 would also be the first diesel in the segment to offer 300 hp (and its accompanying 520 lb-ft of torque led the field in ‘01) and be optioned with what many consider to be the first “true” commercial-grade automatic transmission, the Allison 1000.

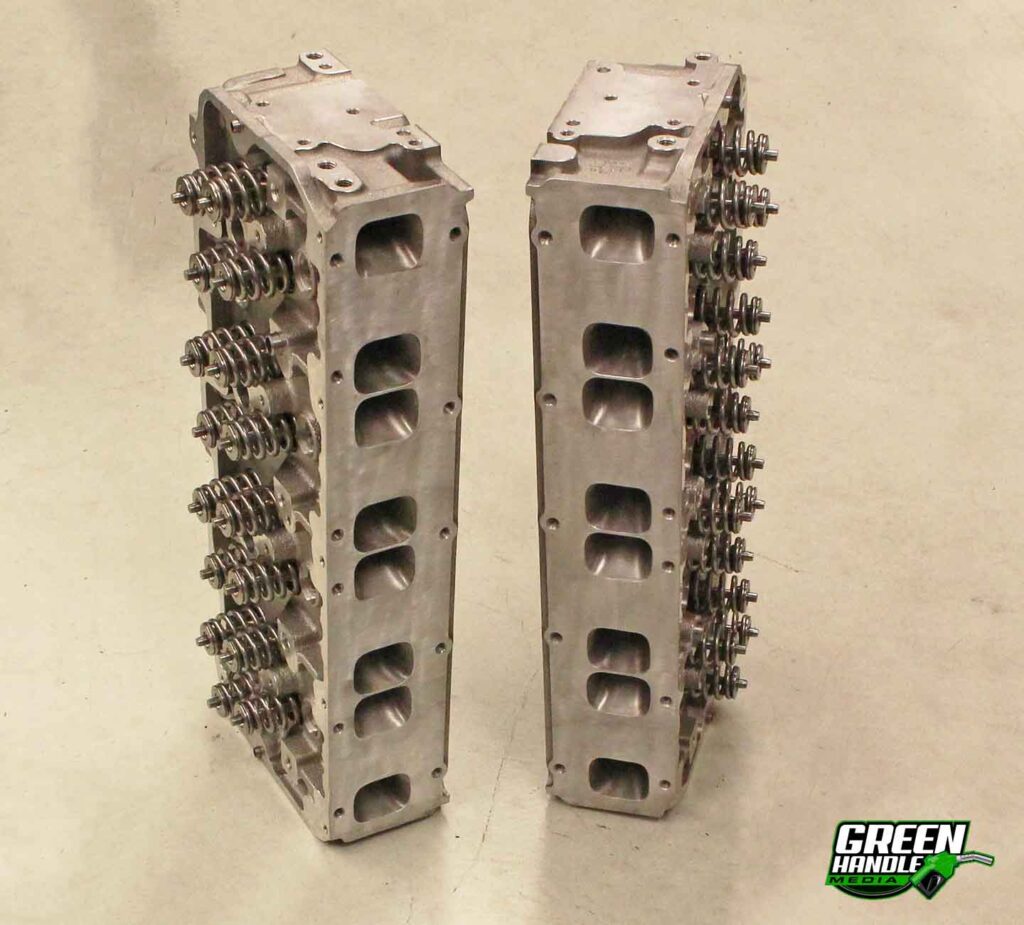

Aluminum Cylinder Heads

Gravity cast in Japan and finished in Moraine, Ohio, the aluminum cylinder heads employed on the Duramax were revolutionary in the world of ¾-ton and larger pickups. The heads employed a 4-valve-per-cylinder design with the valves incorporating a slight twist of their shape relative to the centerline of the crankshaft to provide added swirl for both controlling emissions and maximizing fuel efficiency. Within the heads, hardened valve seats were used, another first for the segment. Each head also utilized two forged-steel rocker arms for each set of intake and exhaust valves. Sufficient head-to-block fastening was accomplished thanks to six head bolts per cylinder (18 per head), making for exceptionally long head gasket life.

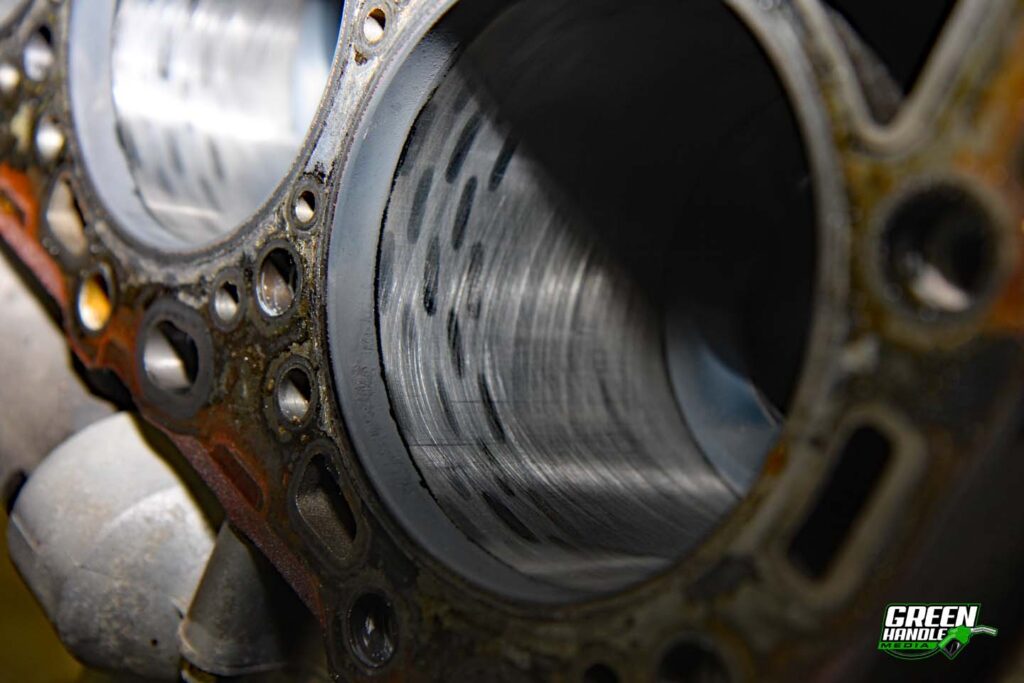

One Tough Bottom End

GM set a target operating life of at least 200,000 miles for the Duramax, a number we now know can easily be doubled, tripled or (in some cases) even quadrupled with proper maintenance. The engine’s high durability starts with its foundation: a deep-skirt, gray iron block with side-bolted main bearing caps, and induction hardening in the combustion area of each cylinder (shown above). The forged-steel crankshaft was Nitrided and Tufftride-treated to increase its fatigue strength, and the connecting rods—which in time the aftermarket would prove could withstand double the engine’s factory torque rating—were of the forged-steel, fractured cap variety. Its lightweight cast-aluminum pistons, boasting an upper compression ring that’d undergone physical vapor deposition treatment, proved highly durable as well.

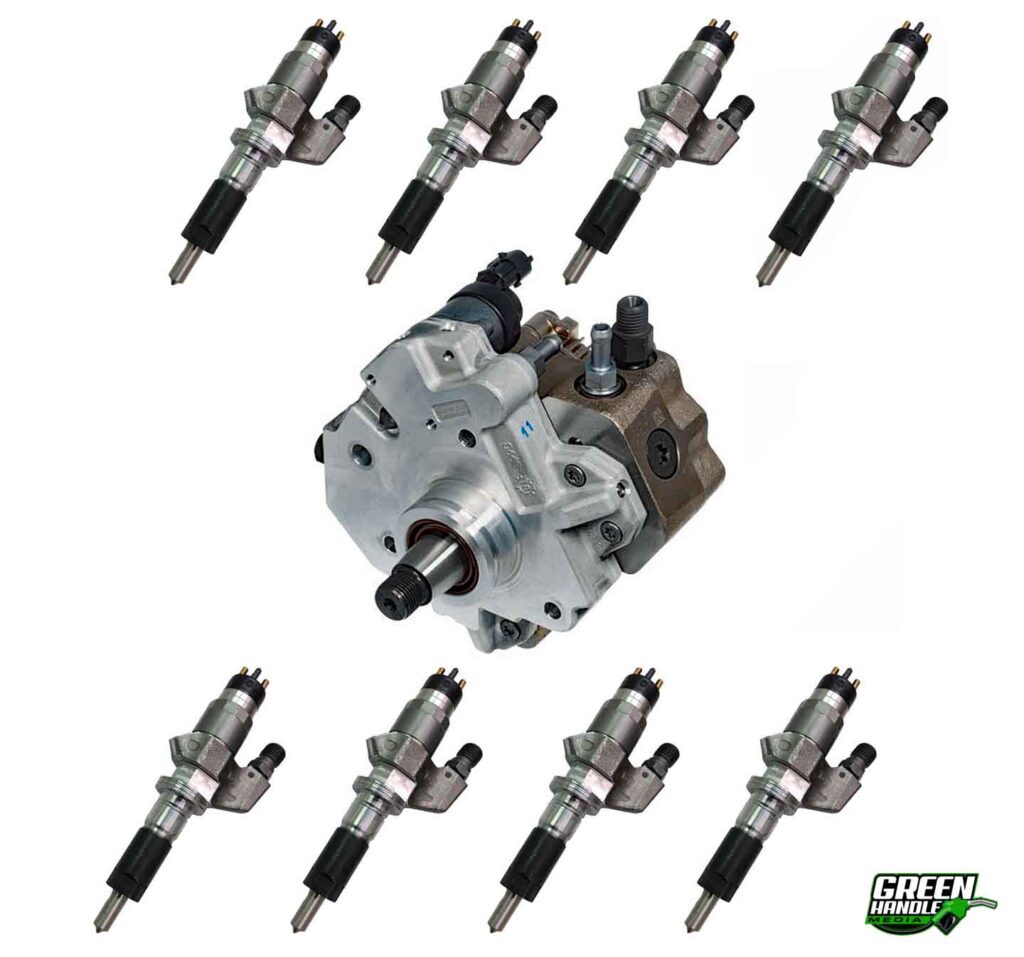

Common-Rail Injection

Perhaps even bigger news than the aluminum heads or the stout bottom end was the Duramax’s use of high-pressure common-rail injection. Debuting common-rail in the diesel pickup segment came in the form of a Bosch-sourced CP3 high-pressure fuel pump and solenoid valve fuel injectors. It marked the first time high-pressure (up to 23,000 psi) could be created independent from engine speed. Electronically controlled, injection timing could be varied across any operating range, or for any condition, and pilot injection—an event occurring prior to the main—worked wonders to quell the infamous injection noise diesel engines were known for. High-pressure common-rail injection provided for best-in-class horsepower and torque, the ability to meet (and exceed) EPA emissions standards at the time, and a quieter, smoother operating engine than the competition.

The Allison Option

Supporting the all-new Duramax was the optional Allison 1000, an electronically controlled five-speed automatic that brought medium duty-like brawn to the diesel pickup division. The Allison boasted a massive, 1.26-inch diameter input shaft, adaptive learning technology to constantly improve shift quality, a modular case design, and a convenient external spin-on transmission filter. The commercial grade automatic was accompanied by a new transmission cooler, mounted below the radiator and that had been upsized over previous versions on GM trucks. Larger, 5/8-inch transmission cooler lines (vs. 3/8-inch lines previously) were also part of the deal, and provided for a very advantageous, 6-gpm flow rate.

A Lesson In Legendary Engine Manufacturing

Leaving the 6.5L and 6.2L engine designs of old behind them, GM wisely leaned on Isuzu’s diesel engine expertise to break ground on a new platform for its HD pickup trucks—a power plant that had to be a homerun. Without its avant-garde injection system technology, the extensive measures taken to ensure durability, and segment-best horsepower and torque ratings, the Duramax never would’ve stood a chance against Ford’s popular 7.3L Power Stroke or Dodge’s new, 24-valve ISB 5.9L Cummins. On all fronts—performance, durability, fuel efficiency, NVH, and cleanliness—the Duramax delivered, and then some. Even today, much of the original design and architecture remains—proof that the 6.6L Duramax was an engine ahead of its time.

Excerpts from the initial GM press release, published December 19, 1999:

“An all-new Duramax Diesel 6600 engine will debut as an optional engine in GM’s 2001 Chevy Silverado and GMC Sierra 2500HD/3500 pickups, Crew Cabs, Big Dooley and Chassis-Cab models, next year. It is positioned to help GM set new industry standards for diesel power, performance, durability/reliability and quiet operation in the growing heavy-duty (HD) pickup class.”

“Duramax Diesel engines will be sourced and manufactured through a brand new manufacturing facility in Moraine, Ohio.”

“When specified, the Duramax will be mated to either a ZF 6-speed manual transmission (std), or an all-new 1000 Series(TM) 5-speed automatic transmission (opt) from Allison Transmission.”

“Targeted ratings are 300 horsepower at 3,100 rpm and 520 lb-ft of torque at 1,800 rpm. Its high, flat torque curve will deliver more power across the power band than any competitor, and will help Duramax 6600- equipped GM HD pickups excel in off-the-line performance, acceleration and heavy-duty trailering and hauling.”

“The new Duramax 6600 posts noise, vibration, and harshness (NVH) figures more typical of similar- sized gasoline engines.GM’s current benchmark status in full-size pickups, Isuzu’s in diesel engines, Bosch’s in fuel injection and Allison Transmission’s in commercial- duty automatic transmissions all combine to ensure that next year GM’s Duramax Diesel-powered HD pickups will achieve benchmark status in the full-size diesel pickup segment.“

Written by Mike McGlothlin