Rise Of The Common-Rail

The same technology that was originally implemented by OEMs to curb emissions ended up being the key to taking diesel drag racing to the next level.

Like all internal combustion engines, diesel’s roots are primitive. For most of its first 100 years in existence, mechanical injection and very few electronics dominated the general makeup of the compression ignition engine. Electronically controlled injection systems wouldn’t enter the picture until the late 20th and early 21st century—technology that was first brought to market at the OEM level in order to meet tighter emission standards. In particular, high-pressure common-rail injection would prove a game-changer, and GM was the first of The Big Three to introduce it, in the form of the 6.6L Duramax in 2001. Cummins would follow suit with the 5.9L in 2003 and Ford/Navistar would get onboard with common-rail technology in 2008.

Soon, the same technology that was implemented to curb emissions—with its higher injection pressures and more precise injection events—was embraced by the aftermarket. And not only did having full control over the injection system make for cleaner burning engines, but factory-like drivability could be retained with tremendous power on tap. Out on the track, common-rail technology was exactly what was needed to take diesel drag racing to the next level. Most record-holders and, indeed, the majority of the competitors you see at diesel events today are campaigning common-rails. To be sure, transmission, turbo, and chassis technology has come a long way as well, but that’s a story for another time. For now, it’s time common-rail injection gets its much-deserved time in the limelight.

Signs The Tide Was Turning

It’s undeniable that diesel drag racing took a momentous leap forward once the industry pivoted toward common-rail technology, and this is one of the trucks that represents that turning point. Firepunk Diesel’s Lavon Miller would claim three consecutive U.C.C. trophies behind the wheel of it, not to mention the fact that it became the first Pro Street truck to run a 7-second quarter-mile and a 4-second eighth-mile. Now in the hands of Justin Zeigler, and with a common-rail D&J Enforcer series Cummins under the hood, it’s the reigning ODSS Pro Street Champ and class record holder, having gone 4.74 at 159 mph in 2023.

Full Electronic Control

At the heart of modern common-rail systems is the ability to precisely control injection timing and quantity via an electronic control unit (ECU). In solenoid-type injector applications, such as with the 5.9L/6.7L Cummins and ’01-’10 Duramax and ’17-present Duramax applications, the ECM can dictate with high accuracy when (and for how long) the solenoid is energized. Better yet, the high-pressure fuel pump present in a common-rail system doesn’t necessarily have to be timed with the engine. In those instances, the pump simply receives low-pressure fuel supply from the tank and pressurizes it for storage in the fuel rail(s).

Remember When?

Rewind the clock to 2009 and you get this gem: Micah Sullivan’s 9-second common-rail second-gen. His Scheid Diesel-sponsored standard cab Dodge was one of the first competition diesels to run a stand-alone ECU. Onboard was a Bosch Motorsport MS15.1 wired and calibrated by Andrew Stauffer, who worked for Bosch Motorsport at the time and who was also directly responsible for bringing stand-alone ECU’s to the U.S. diesel market. Today, Stauffer co-owns S&S Diesel Motorsport—an industry leader in common-rail fuel systems and electronic controls. Coincidentally, Sullivan’s nasty Pro Street machine was also one of the first to campaign a GT55-based single turbo in the form of Precision Turbo & Engine’s Pro Mod 88. The Scheid-built 5.9L Cummins, which made use of a stock CP3 and a monster-sized and belt-driven pump coined a “CP10,” produced 1,800hp on the dyno and turned 5,000 rpm going down the track.

Stand-Alone ECU’s

Naturally, the factory ECU in a late-model diesel truck has its limitations—especially for a motorsport application. As the need for further control of the common-rail system, higher rpm, and more engine parameters continued to grow, stand-alone ECU’s began to steadily infiltrate diesel drag racing. With the touch of a button on a keyboard, problems can be solved, more power can be made, or a more successful launch can be executed. Bosch Motorsport and MoTeC are the major players in town here, and the folks at S&S Diesel Motorsport are familiar with both systems. The company even worked hand in hand with MoTeC to develop a diesel-specific software package for seamless integration of the units like the M142 shown here. S&S offers full calibration support, and tunes various race teams’ ECU’s.

MoTeC’s Breakthrough In Diesel Drag Racing

Ben Shadday was one of the first Outlaw Diesel Super Series drag racers to adopt MoTec ECU technology, and his Pro Mod class ’63 split-window Corvette didn’t disappoint. It would end up living in the deep 4’s and turning in trap speeds approaching 180 mph. The C2 ‘Vette was built by HammerTech Racecars, was powered by a billet-aluminum CX series Cummins from Wagler Competition Products, made use of S&S top-feed style injectors and a pair of stroker CP3’s, and also received the big single turbo, nitrous treatment.

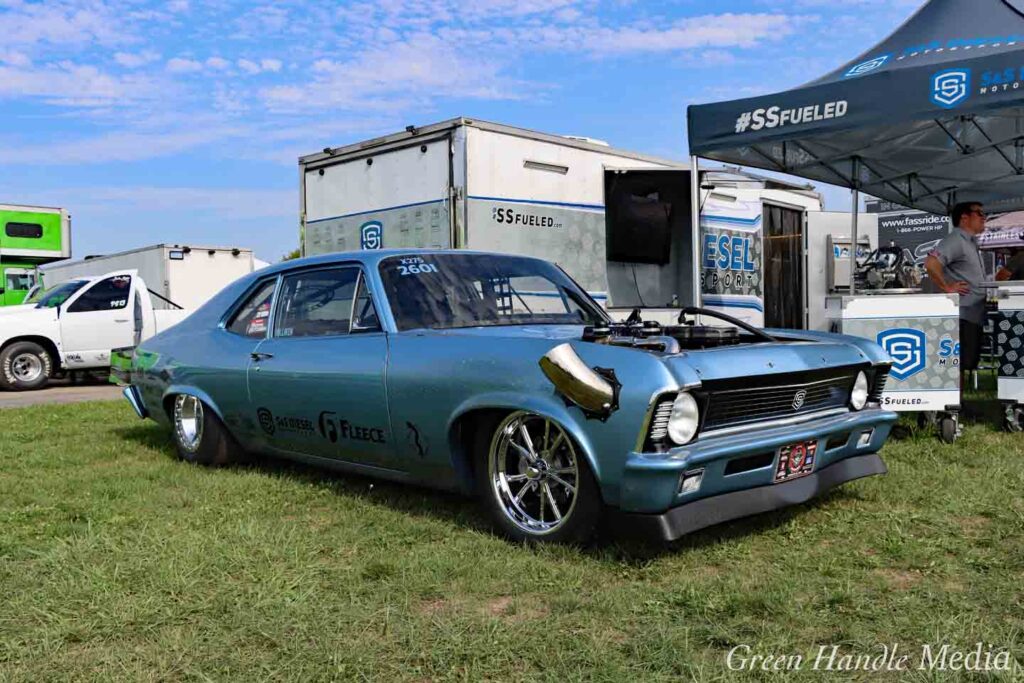

Winning On The Big Stage

This is the car that’s taken the world of radial tire drag racing by storm: Ryan Milliken’s X275 class ’69 Nova. The Glacier Blue beast recently won No Mercy 14 and the Snowbird Outlaw Nationals. The engine, an S&S fueled, MoTeC controlled Freedom Racing Engines Cummins, makes use of everything S&S brings to the table. Luke Langellier, Co-Owner of S&S Diesel Motorsport, weighed in by saying: “I’m not sure there’s a sport out there that has progressed more in the last few years than diesel drag racing. I may be biased, but S&S invested heavily in progressing the electronics capabilities and complementing next-level fuel systems, which had a huge part in that. Nobody is able to do much without those two key pieces of the puzzle.”

Competition Injectors

A lot goes into the making of a race-ready common-rail diesel fuel injector, but the general gist for success is this: big nozzles, properly matched needle lift, correct spray angle, the necessary body modifications, and appropriate balancing. The industry’s realization that big, high-flow nozzles (which, when combined with the proper body modifications, facilitate shorter duration and a quicker injection rate) were actually much safter for the engine—especially in terms of heat and keeping the spray pattern contained within the piston bowl—paved the way for the winning combinations we see so often today. Common recipes that call for 400-percent over injectors and a pair of stroker CP3’s are par for the course, and the engines running this arrangement—engines that belt out 2,000, 2,500 and even 3,000 hp or more—often last an entire race season.

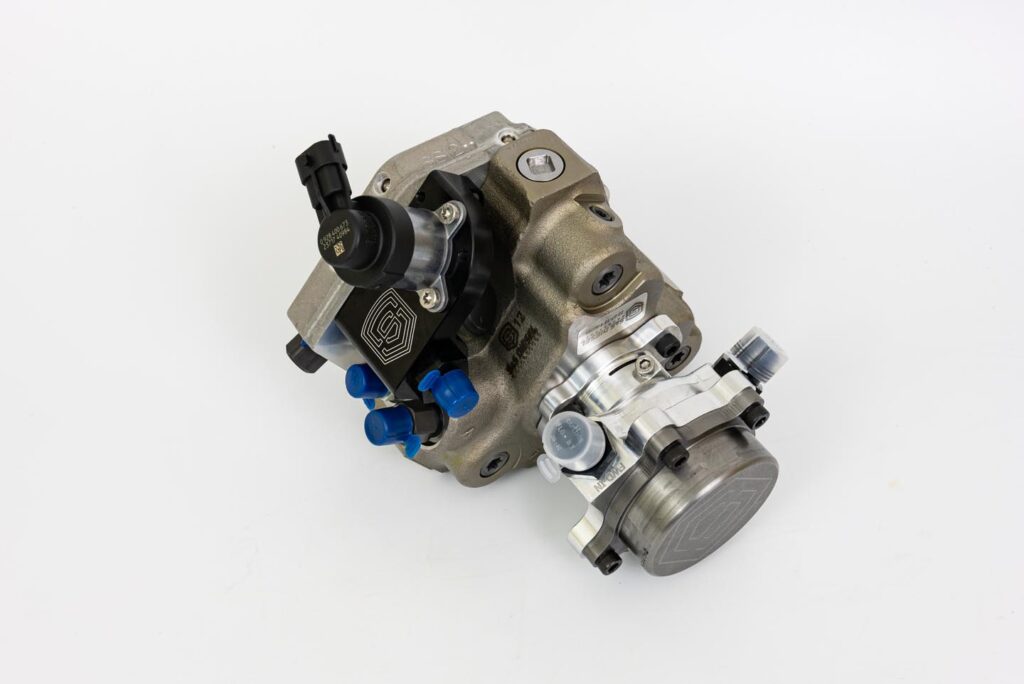

Stroker Pumps

To realize the full potential of a set of 400 or 500-percent over injectors, high-pressure fuel pumps that can maintain rail pressure are paramount, and this is one area where huge advancements have been made in recent years. As for the CP3 platform, the most commonly employed pump in diesel motorsports, 10mm, 12mm, and 14mm stroker pumps are all available—the latter two pumps especially having made it possible to get away from running dual CP3’s in many applications. These pumps sport increased stroke camshafts, modified factory or completely redesigned buckets, and high-speed versions can support engine speeds in excess of 5,500 rpm.

Supporting Parts

Pressure spikes are normal in common-rail systems, but a functioning pressure relief valve keeps those spikes from causing damage. This becomes even more important in motorsports, where elevated rail pressures (pressures in excess of 32,000 psi) are often commanded. To match the extreme rail pressures seen in racing, S&S offers 2200 bar (31,900 psi) and 2400 bar (34,800 psi). These components might not sound as glamorous as a CP3 or a set of injectors, but they’re every bit as important when it comes to pushing the limits in diesel motorsports.

The Importance of Low-Pressure Fuel

Of course, none of the magic would be allowed to happen in a common-rail system without proper pressure and volume first being supplied to the high-pressure pump(s). The SP3000, yet another product developed by the common-rail experts at S&S, is a mechanical solution to low-pressure supply problems in high horsepower applications. The bolt-on unit, used in conjunction with the company’s regulated filter head, simply marries to a CP3. The compact supply pump can support up to four 14mm CP3’s, boasts a flow rate of nearly 2,800 LPH and has been tested to a maximum pressure of 400-psi.

Quickest Eighth-Mile Diesel: Common-Rail

For several years now, the diesel record books have been all but dominated by common-rail power plants. Michael Cordova’s record-setting rail is no exception. After Mattie Graves’ twin-turbo Duramax-powered dragster moved the eighth-mile high mark deeper into the 3.90s, Michael laid claim to it last fall—in the form of a 3.87 at 191 mph. His HammerTech-prepped, Spitzer chassis rail makes use of a Cummins that’s equipped with a Scheid Diesel billet-aluminum block, a Freedom Racing Engines’ cylinder head and billet intake manifold, and a Stainless Diesel GT55 that’s surrounded with top-notch, 1X Precision intake and exhaust plumbing. S&S handles all of Michael’s fueling, ECU (by way of MoTeC) and tuning needs.

Quickest ODSS E.T. & MPH.: Common-Rail

Pro Mod driver, Johnny Gilbert, wasted little time establishing his Cummins-powered ’63 Corvette as a top-tier car in the Outlaw Diesel Super Series. In 2023, he and the Stainless Diesel team put up a 4.14-second eighth-mile at 177 mph at the first race of the year—ODSS records that would stand for the duration of the season. The nasty, split-window Corvette is graced with a CX400 series, billet-aluminum Cummins from Wagler Competition Products. It features top-feed, Iveco-based injectors, dual 12mm reverse rotation (and gear-driven) CP3’s, and an SP300 supply pump from S&S, full MoTec control, and a Stainless GT55. And thanks to help from Scheid Diesel, HammerTech Racecars, and Nitrous Express, elaborate water-injection and nitrous systems are onboard, too.

Written by Mike McGlothlin