Averting Catastrophe With S&S Diesel Motorsport’s CP4 Disaster Prevention Kit

You can’t keep your 6.7L Power Stroke’s CP4 from self-destructing—but you can ensure it doesn’t wreck the entire fuel system if it does.

Any time you can spend hundreds in order to save thousands, it’s a good investment. Since the 2011 model year, Ford has been using the Bosch CP4.2 high-pressure fuel pump on its 6.7L Power Stroke engines, and for the duration of that time it’s been a ticking time bomb. Granted, some of them go 200,000 miles (and even beyond) without skipping a beat. Others self-destruct inside of 100,000 miles, leaving you with a trashed injection system and a repair bill that exceeds $10,000. Since 2016, S&S Diesel Motorsport has been providing 6.7L Ford owners with peace of mind thanks to its CP4 disaster prevent kits, and the latest version, the Gen2.1, represents the company’s best work yet.

A complete, bolt-on proposition, the Gen2.1 CP4 disaster prevent kit ensures that the high-pressure fuel pump’s case and metering unit are independently supplied with clean, filtered fuel. In the event of a CP4 failure, the 6.7L Power Stroke’s injectors, rails, lines, tank, and lift pump are left completely free of debris thanks to a 9-micron Donaldson return filter that traps pump debris before it has a chance to be sent back to the tank. S&S Diesel Motorsport’s Gen2.1 CP4 disaster prevent kit has even proven effective enough to extend the range of a truck that’s lost its CP4. We recently installed the system on an ’18 F-250 that’s regularly hooked to 15,000-pound trailers. The owner reports a newfound level of contentment, especially on out-of-state trips.

The contents of the S&S Diesel Motorsport Gen2.1 CP4 disaster prevent kit include a billet-aluminum bypass block, high-quality fuel hose with OEM style quick-connect fittings, and a billet-aluminum filter head complete with a mounting bracket that accommodates rubber isolators to dampen noise/NVH transfer from the filter into the cab. The return filter itself is a 9-micron, spin-on Donaldson unit. One size fits all, the Gen2.1 CP4 disaster prevent kit boasts a single part number, with the system fitting every 6.7L Power Stroke from ’11-present. So, what’s the price for peace of mind in knowing your injectors, rails, fuel lines, lift pump, and tank are safe in the event of a CP4.2 failure? $400.

Without question, gaining access to the CP4.2 is the most time-consuming part of installing the Gen2.1 CP4 disaster prevent kit. After the air intake tube that spans between the air filter box and lower intake was out of the way, we removed the upper intake’s 15 8mm bolts. For the rearmost upper intake bolts, we put a wobble socket to good use. It’s also worth noting that one bolt serves a dual purpose in securing the engine oil and transmission fluid dipsticks to the upper intake. On the way out, the upper intake barely cleared the truck’s cowl, but by gently prying upward on it we were able to finagle it free.

Removal of the lower intake is also necessary and, in addition to loosening its three 10mm mounting bolts, calls for disconnecting the crankcase breather and the clamps that secure the intake to the turbocharger. It also requires disconnecting the electrical connector from the intake throttle body. For ease of removal, as well as added working space, we opted to pull the hot-side intercooler pipe. With the lower intake gone, we hit the lifter valley with compressed air, followed by brake cleaner, to ensure the space was clean when pulling the CP4.2 pump’s metering unit.

Easily reachable at this point, the fuel volume control valve (i.e. FCA, or metering unit) was unbolted and carefully removed from the CP4.2. When a CP4 is suspected of failure, pulling the metering unit is the first meaningful way to diagnose it. Finding debris on the metering unit’s screen—what happens when a piston rotates in its bore and allows the roller tappet to dig into the cam—provides confirmation that the high-pressure fuel pump has begun to come apart. Being that our disaster prevention kit recipient was running perfectly fine prior to tear down, there was predictably nothing present on the metering unit’s screen.

With the FCA out of the way, the S&S bypass block (complete with the supplied O-rings) can be installed. The bypass block is a key piece in the disaster prevention kit. It doesn’t allow fuel from the CP4’s case to flow into the metering unit (and on to the pumping elements from there). Instead, the pump case and metering unit are supplied fuel separately. By stopping fuel from the pump’s case from being fed to the metering unit, the debris created by a bottom end failure (the primary failure point) can’t move into the high pressure chambers, out to the rails, and on to the injectors. In fact, the debris is routed back into the return circuit, where the return filter in the S&S kit collects all of it.

It’s easiest to install the bypass block and metering unit as a single assembly and with the supplied, front-most 4mm Allen bolt already in place. You’re dealing with very tight quarters here thanks to the engine coolant crossover tube. With the front Allen bolt’s threads started, we installed the remaining Allen bolt and threaded it fully in, then turned our attention back to the front bolt. We used a 4mm ball-end Allen wrench to get this fastener started, taking special care not to cross-thread the bolt into the CP4. Both bolts would ultimately be torqued to the 60 in-lb spec listed in S&S’s detailed instructions.

Once the bypass block is in place, virtually every OEM component removed during teardown was reinstalled (lower intake, crankcase breather hose, cold side intercooler plumbing, upper intake, etc.). As for the upper intake, it pays to make certain you’ve reattached the dipstick tubes to it before you move on to reinstalling the factory fuel filter housing (shown). The fuel hose with the red quick connect tab on the right is part of the split hose arrangement that’s part of the bypass block. The reason this split occurs two feet away from the CP4 is intentional and eliminates the chance of contaminated case fuel back-feeding into the clean fuel supply line.

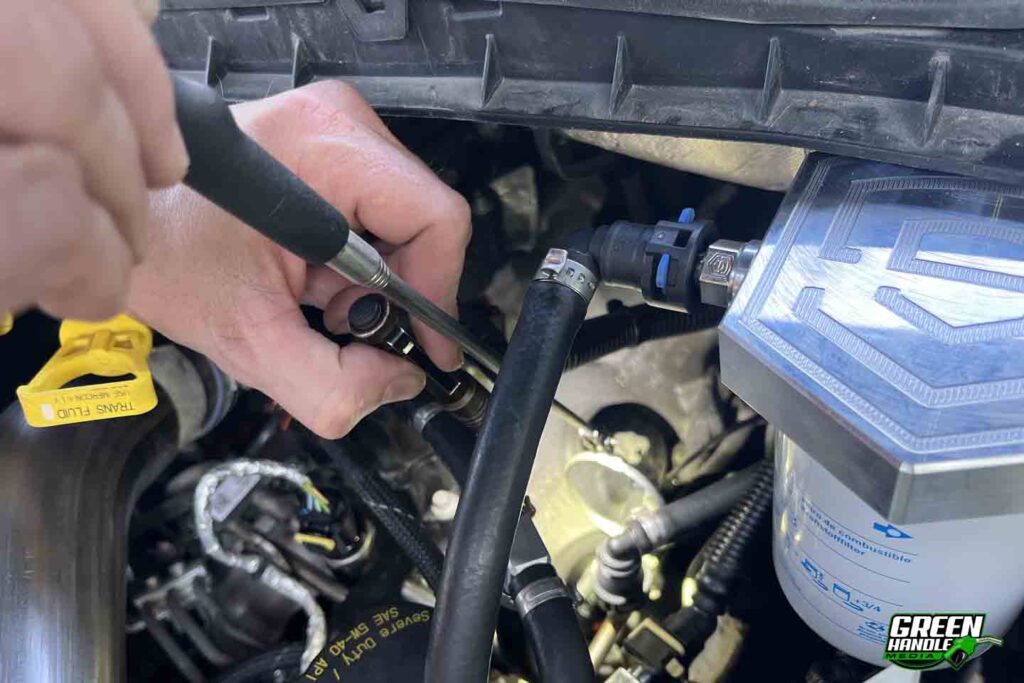

Moving on to the billet filter head assembly, the supplied fittings were equipped with the appropriate O-rings and threaded in. Both fittings were tightened to 10 ft-lbs (120 in-lbs) via a torque wrench and 15mm socket. From there, the supplied rubber isolators and filter head mounting bracket were installed by threading the isolators, hand-tight, into the back of the filter head (shown). That was followed by installing the included serrated flanged nuts on the isolator bolts and tightening them up using a 7/16-inch wrench.

On ’17-newer model year Super Duty’s, the driver side cowl has to be unclipped in order to access the hole that’s used to mount the filter head assembly. There are three clips along the bottom and front of the cowl, while a pair of clips are employed underneath the cowl up top (which calls for gently prying up on the cowl in order to remove them). If you break one of these cowl retaining clips (we did), S&S conveniently includes a replacement part number (PN W708771-S300). Once the hole near the brake fluid reservoir was accessed, the supplied long bolt, spacer, and nylon lock nut was used to mount the filter head using a 10mm wrench (on the lock nut) and a 4mm Allen wrench (bolt head).

Routing and connecting the fuel hoses entailed tying into the factory return circuit, as well as connecting the return-to-tank and return-to-engine hoses. In this photo, the hose that returns fuel to the tank is being attached to the return filter head assembly. The other end, which came pre-fitted with an aluminum barb fitting, was installed into an OEM quick-connect fitting that was disconnected (and rotated upward) earlier on in the installation.

At the opposite side of the filter head (right side as shown here), the return fuel from engine side, the supplied hose with a plastic quick-connect at each end was installed on the OEM metal barb fitting. At the other end, the blue plastic quick-connect (shown) was attached to the previously installed barb fitting in the filter head. The hose was then routed around the back of the return filter. Return fuel leaving the engine flows through the hose on the right, through the filter head and filter, and back to the tank via the hose to the left of the filter head.

A Donaldson fuel filter is responsible for catching the debris produced during a CP4 failure. It boasts a 9-micron rating at 99-percent efficiency, carries part number P550943, and can be ordered individually or in bulk (12) directly from S&S (PN CP4-BP-G2.1-RF12). Its replacement interval is straightforward and is the same as the other fuel filters on a 6.7L Power Stroke, which for normal operating conditions means every third oil change, every 22,500 miles, or as indicated by the truck’s message center. Under “Special” operating conditions, it should be changed every 15,000 miles (or 600 hours). Prior to installing the spin-on Donaldson unit, its O-rings were lubricated with a touch of fresh diesel fuel.

It’s worth mentioning that an extra step is involved for ’20-newer Super Duty owners. On the latest version of the 6.7L Power Stroke, the supplied hose and quick-connect barb assembly pictured is required on the supply side. Its installation calls for a heat gun to remove the OEM hose from the factory hard line it taps into. Whether you need it or not, this piece is included in every disaster prevention kit, and is the reason why S&S has every 6.7L Ford owner covered (’11-present) with a single, comprehensive kit.

With the disaster prevention kit all but installed, we spent some time installing the supplied zip tie hose clips and ensuring everything looked as clean as possible under the hood. Key points of interest here included making sure the hoses were secured in a way that no chafing could occur on nearby components, and namely that the factory fuel supply line didn’t rub the brake booster or brake fluid reservoir. We employed the remaining zip ties at the crankcase vent and near the oil filler neck.

Once the air intake assembly was reinstalled, it was time to purge air out of the fuel system and check for leaks. After cycling the ignition to the accessory position three times we started the engine and, using a telescoping inspection mirror and flashlight, checked each connection point with the engine idling. With S&S’s Gen2.1 CP4 disaster prevention kit now in place, the truck’s owner has peace of mind knowing his injection system (less the high-pressure fuel pump) and low-pressure system will be safe if the CP4.2 ever cuts loose. On top of that, he’s decided to keep his Super Duty for the long-haul instead of trading it in.

Written by Mike McGlothlin